Новости

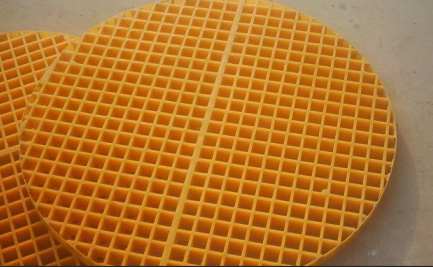

Here is Fiberglass Flanges Supplier talking about Glass fiber production method.

If you have any idea about Fiberglass Flanges, welcome to contact us and discuss.

The production methods are roughly divided into two categories: one is to directly form the molten glass into fibers; the other is to first make the molten glass into a glass ball or rod with a diameter of 20 mm, and then remelt it in various ways to make a diameter of 3 ~ Very fine fiber of 80 μm. An infinitely long fiber drawn by a mechanical drawing method by a platinum alloy plate is called a continuous glass fiber and is generally called a long fiber. Non-continuous fibers made by rolls or air streams, called fixed length glass fibers, are commonly referred to as short fibers. Fine, short, floc-like fibers made by centrifugal force or high-speed airflow are called glass wool. Glass fiber can be processed into various forms of products, such as yarn, roving, chopped strand, cloth, belt, felt, board, tube and so on.

Wave tubes are divided into different grades according to their composition, nature and use. According to the standard level (see table), E-grade glass fiber is the most common and widely used in electrical insulation materials; S-class is special fiber, although the output is small, but it is very important, because of its super strength, it is mainly used for military defense, such as Bulletproof box, etc.; Class C is more chemical resistant than Class E, used for battery separators and chemical filters; Class A is alkaline glass fiber for the production of reinforcing materials.

Looking forward to receiving your inquiry sales@frpwt.com.

Предыдущая страница: The Main Use Of FRP

Следующая страница: How Are The Glass Fibers Classified By Composition?